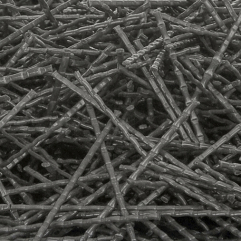

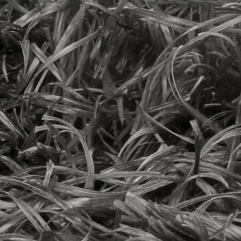

Polymer fiber production

FiberMix offers a cost-effective and reliable solution for all construction needs

Contractors and engineers from all over the world recommend the use of different types of concrete filled with synthetic fibres and other materials that can enhance different aspects of the construction where it’s being used. However, no other store in the United Kingdom can provide to its customers a solution for the quality and cost that FiberMix does. The products and solutions offered by this store are many. They are tailored for the needs and applications of each customer. However, in all the products that people will encounter in our locations there will be a few common but key aspects, such as:

- all or materials are independently tested and verified in order to ensure its compliance with modern standards;

- all our fiber for concrete materials have been developed by engineers and construction specialists;

- all our solutions are constantly improved upon the feedback received from our customers;

- and what’s also very important, all our solutions are cost-effective!

Whenever customers want to inquire about our products, they will be put in contact with one of our specialists. They will work together in finding the right material and properties that will be perfect for their project.

Features of polypropylene fibres for concrete

Firstly, we should start by mentioning why polypropylene fibres are added to concrete in the first place. Concrete by itself is a very reliable, solid and stable material. However, certain projects for different reasons might need the strength of concrete and a few properties. Fibres are added to the screed material in order to increase its ductility and toughness.

But that’s not all, because there are a few important features of these fibres that improve upon the great benefits that concrete already presents. For example, the material will have a higher tensile strength. It will also improve its resistance against fatigue and it will reduce crack growth. Finally, adding fiber concrete will greatly increase its resistance against impacts.

Which fibres can be added to concrete

There are many different fibres that may be used for reinforcing concrete. For example, it is possible to add polymer and carbon fibres. They have great properties like reduced thermal expansion, have a great tensile strength and are highly resistant to chemical contact.

Polypropylene fibre is another kind of material that can be used to reinforce concrete. This material has a few advantages over other fibres. First, it can be a great insulator against contaminants from organic and non-organic origin. On the other hand, it makes the concrete highly impermeable, meaning that water will not be an issue in the place where it is being used.

Our production:

Benefits of fiber to concrete

There are numerous other ways in which fiber concrete can be superior to standard concrete. For example, it is possible to increase its resistance to bending, and protect the material against shrinkage effect. Another great example is fiberglass. This material has some of the reinforcement properties like carbon fibres and micro fibres such as great thermal resistance, but at a fraction of the cost.

Advantages of cooperation with FiberMix

FiberMix is a company where specialists in concrete, construction and engineering use their experience to offer the best solutions to their customers. Also, everything offered by FiberMix is cost-effective. When this is combined with the high standards that all FiberMix products satisfy, it is easy to see why this is the best place to source any fiber for cement mix.

Mixfiber FAQ

Where does polypropylene fiber is used?

Polypropylene is a versatile material that can be used in a variety of applications, including concrete. It is known for its resistance to drying shrinkage and plastic shrinkage, making it an ideal choice for many construction projects.

What reinforcing fibers for concrete do you produce?

The TM Fibermix catalog includes ArmoTech synthetic fiber for structural reinforcement, PolyMesh macrofiber, polypropylene microfiber for concrete and screeds.

Why polyolefin fiber reinforcement is better than using steel

Polyolefin fibers are a type of synthetic fiber that is lighter than steel fibers. They have no reactions with water, which makes them ideal for reinforcing concrete. Polyolefin fiber reinforced concrete has been shown to be more resistant to corrosion and cracking than concrete made with steel fibers.

Is Fibermix® fiber environmentally friendly?

Polymer fiber is an environmentally friendly material that is completely safe for humans and the environment. The fiber strands consist of pure polyolefins, making them environmentally harmless.

During the production and use of polymer fibers, no harmful substances are released into the atmosphere. The material is approved for use in the construction of residential and industrial buildings.

Does the consistency of concrete change when fiber is added?

The fibers of microfiber and macrofiber, when added to the concrete mix, are distributed throughout the entire mass, thereby changing the properties of the building material in every part. At the same time, the introduction of synthetic fibers into the concrete mixture leads to a decrease in concrete density and an increase in its stiffness.

To achieve the desired consistency, you can additionally use a concrete plasticizer or a superplasticizer. Water should not be used to thin the mix.

How to choose Fibermix® fiber correctly?

The fibers can vary in size: length from 3 to 40 millimeters, diameter up to 30 microns. The fiber for concrete is selected depending on the purpose of the mix:

- for industrial floors and cement concrete road surfaces – fibers 12, 20, or 40 mm;

- in the production of cellular concrete (foam concrete, aerated concrete) – fibers 20 or 40 mm long;

- for screeds, underfloor heating, reinforced concrete structures and products – 12 or 20 mm;

- for heavy mobile concrete – length from 12 to 20 mm;

- for paving slabs and small concrete products – 6 or 12 mm;

- for dry construction mixes – fibers 3, 6, or 12 mm long;

- for household use – from 3 to 6 mm.

What is the price of polymer fiber?

Fiber manufacturers can offer a wide range of conditions for their clients, as well as a large selection of polymer additives. Therefore, it is important to be attentive in order to choose the right option. The polypropylene fiber manufacturer Fibermix® has many years of experience, so its products meet high-quality standards. You can buy fiber for concrete on our website and see for yourself that its price remains affordable.