Do you want to reinforce an industrial concrete floor? Are you thinking about how to make the floor in a production facility or warehouse resistant to loads? For this purpose, Fibermix produces polypropylene macrofibers under the Polymesh trademark.

Macrofiber PolyMesh®

MACROFIBER

increasing concrete tensile strength in bending

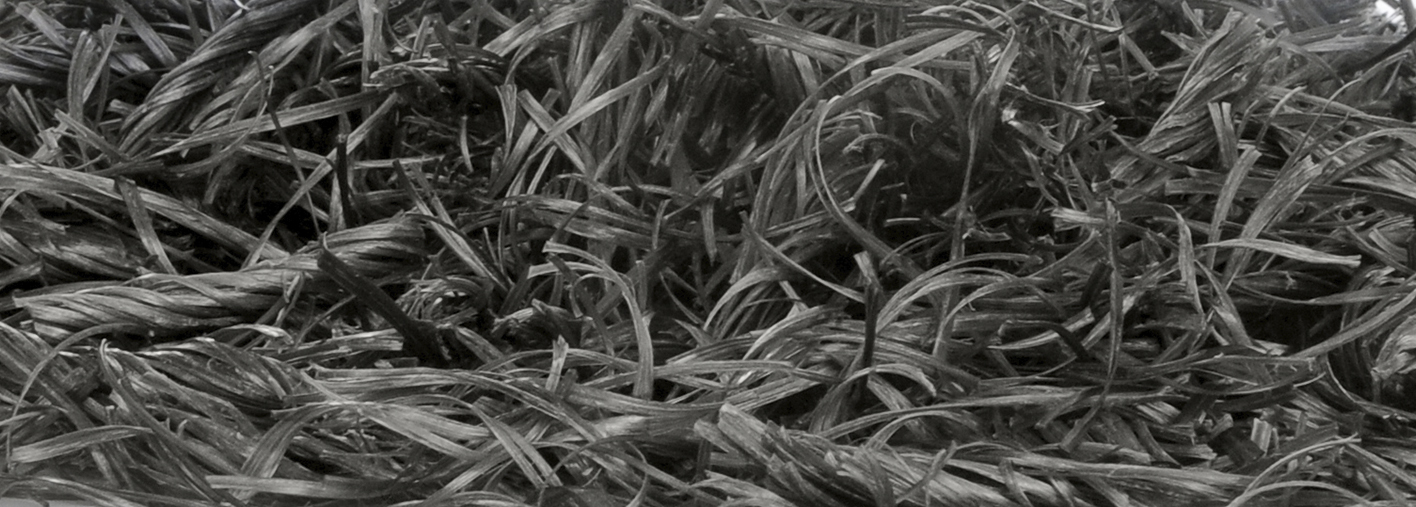

PolyMesh® is a structural macrofiber made of 100% virgin polypropylene, which has been thermally, chemically and mechanically modified. Perfectly distributed in the volume of the mortar, the fibers create a highly effective three-dimensional concrete reinforcement system.

PolyMesh® is used to reduce shrinkage of plastic concrete, increase impact strength and absorb energy of destruction. This ultra-strong fiber provides maximum durability, structural improvements and effective control of secondary and thermal cracks.

PolyMesh® fibers are cheaper, more environmentally friendly and lighter than steel reinforcements.

Order on our website Mixfiber.

Specifications

| Price (1 kg) | 4.6 EUR |

| Composition | Dyed polyolefin |

| Density | 0,91 g/сm 3 |

| Fiber length | 38 / 54 mm (± 2) |

| Single fiber equivalent diameter | 0,32 mm |

| Chemical resistance to acids and alkalis | excellent |

| Tensile strength | 500-600 MPa |

| Elastic modulus | not less than 4 GPa |

| Melting point | 160 °C |

| Ignition point | 350 °C |

| Absorption | zero |

| Colour | graphite |

| Quantity in 1 kg, not less | 150000 pcs |

Certificates

Macrofiber PolyMesh® product description

- Increases flexural tensile strength

- Reduces plastic shrinkage and cracking in concrete

- Absorbs the energy of internal stress

- Increases resistance to impact and destruction

- Increases frost resistance, removes the risk of corrosion

- Reduces wear on concrete pumps and hoses

- Chemical inertness and resistance to alkalis and acids

- Cost effective alternative to steel mesh and steel fiber

The minimum dosage for PolyMesh® starts at 1 kg / m3. The recommended dosage range for PolyMesh® is 2 to 8 kg / m3. PolyMesh®, used at the appropriate dosage, is the ability to replace steel fibers, welded mesh, or significantly reduce conventional steel reinforcement. PolyMesh® fibers are a safe and easy-to-use alternative reinforcement system that is resistant to alkaline concrete where high chemical resistance is required.

PolyMesh® fibers are added to the concrete grout at any stage of concrete preparation. Place the required number of water-soluble fiber bags into the mixer of the concrete mixer. For even distribution of fibers, it is necessary to stir the mortar for 6-8 minutes. Before supplying fresh concrete at the facility itself, the concrete mixer must be rotated at maximum speed for 2 minutes. PolyMesh® fibers are designed to distribute evenly throughout the solution when mixed with other components.

- Packaging: White branded paper packs of 1 kg;

- Packing in a box: 38mm - 10 kg per box = 10 packs of 1 kg, 54mm - 12 kg per box = 12 packs of 1 kg;

- Quantity per pallet: 38mm - 300 kg = 30 boxes of 10 kg, 54mm - 360 kg = 30 boxes of 12 kg;

- Size of a pallet with the goods 1,0*1,2*2,3 m

Delivery

- DELIVERY WORLDWIDE

The FiberMix company can organize delivery of any amount of goods by land or sea and to any country which is requested by our customers

The company's managers will offer you the most convenient conditions for the delivery of fiber to your facilities or warehouses.

Our company is guided by the interests of our customers and delivers as soon as possible.

DELIVERY ACROSS ENGLAND, USA

DELIVERY ACROSS ENGLAND, USAOur company uses the services of international freight transportation in curtain trailers and cargo transportation by sea containers.

The company's managers will offer you the most convenient conditions for the delivery of fiber to your facilities or warehouses.

Our company is guided by the interests of our customers and delivers as soon as possible.

Macrofiber PolyMesh® : Reviews

Doflika

27.07.2024

I am excited to share my experience with polypropylene fiber for reinforcing concrete. I recently used this material for a project and was impressed by how well it integrated with the concrete mix. The fiber significantly enhanced the strength and durability of the concrete, making it more resistant to cracking and wear. It's a fantastic solution for anyone looking to improve the longevity of their concrete structures. I highly recommend polypropylene fiber for anyone undertaking similar construction projects

Answer

Macrofiber PolyMesh®

- What is PolyMesh® polymer macrofiber?

With PolyMesh® polymer fiber, you can reinforce the entire volume of your concrete. At the same time, you comprehensively improve the performance of your product due to the uniform distribution of fibers throughout the entire volume of concrete. When vibrating concrete, PolyMesh® does not sink into the lower concrete layer under its own weight, as it does with steel fibers.

Polymer macrofiber - fibers used to reinforce various mortars, in particular, concrete. It significantly increases the strength, as well as other technical characteristics of concrete products during operation. Today, such material as polymer macrofibre is in great demand in private and commercial construction.Polymer macrofiber in Ukraine

The introduction of modern technologies and materials into construction processes allows the industry to be optimized to the maximum. One of these innovations is polypropylene (polymer) fiber - it will not be difficult to buy material in Ukraine, but this issue should be approached as seriously as possible.

In order to purchase a really high-quality product, it is better to start cooperation with manufacturers. FiberMix® is a full-cycle manufacturer, we independently purchase raw materials, manufacture and sell the product. Ready-made polypropylene (polymer) macrofiber - the price of reliable, strong, durable concrete.Fiber can be ordered in any required quantity at an acceptable cost. FiberMix® offers its customers exceptional quality, confirmed by appropriate certificates, and favorable terms of cooperation. You can buy such material as polypropylene (polymer) macrofiber from us.

The stresses arising from concrete deformations are relieved due to a large number of low-density fibers (more than 320 thousand per m3).

PolyMesh® macrofiber is the best alternative to steel fiber.

- What are the most important benefits of PolyMesh® polymer macrofiber?

The most important benefits of fiber

In order not to be unfounded, let us dwell on the main advantages of the material that allow it to occupy a leading position in the modern market.- Fire safety. Buy high-quality polymer fiber for concrete, Ukraine significantly increases the fire resistance of the structure. Classic reinforced concrete contains enough moisture inside, which evaporates when heated, increasing pressure and leading to an explosion of concrete and destruction of parts of the building. The used polypropylene (polymer) fiber prevents this danger, since when heated it breaks down into harmless elements, forming channels through which steam can safely escape without the threat of an explosion.

- Corrosion resistant. Fibers are chemically inert material, they are resistant to alkaline and acidic environments, and are resistant to moisture. Therefore, polypropylene (polymer) fiber for reinforcement significantly increases the service life of concrete structures

- Impact resistance. The addition of macrofiber allows it to withstand significant loads, shocks, vibrations. It is often used when pouring concrete floors, increasing their wear resistance. Even if a massive object falls, the fiber-reinforced floor will withstand the impact without negative consequences.

- Minimum shrinkage factor. Another reason why polypropylene (polymer) fiber for concrete (you can buy in any quantity) is better than other materials for reinforcement. During dehydration, the structure practically does not lose in size, therefore, concrete can be poured into the formwork without taking into account shrinkage.

- Reduced labor costs. Quality concrete fiber is the price of a fast concreting process. Unlike classic rebar rods, it is enough to add fiber fibers to the concrete solution. Thus, the terms of construction work are reduced and their profitability is increased.

- When should you add PolyMesh® polymer macrofiber to concrete?

PolyMesh® polymer macrofiber is added to the concrete mix during or after loading the desired components and mixed according to the concrete manufacturer's recommended standards.

- Is PolyMesh® polymer macrofiber evenly distributed throughout the concrete?

Yes. The uniform distribution primarily depends on the type of fiber, as well as its quantity and the mixing process, equipment, the properties of the polymer macrofiber used and the mixing time. The main factors for uniform distribution are the physical shape of the fiber.

- Is it possible to use PolyMesh® polymer macrofiber in aerated concrete?

Yes, PolyMesh® polymer macrofiber is used in aerated concrete.