Fiber types and the differences between them

The term "fiber" originates from the Latin word "fibra," signifying a thread-like structure or filament. In the context of construction materials, fiber constitutes an essential component in concrete technology, representing discrete filamentous elements of varying lengths employed for both micro- and macro-scale reinforcement of cementitious composites.

Fundamental Principles of Fiber Reinforcement

Fiber is utilized for dispersed reinforcement of concrete structures, a technique that involves the uniform distribution of numerous individual microfilaments throughout the entire volume of the concrete matrix. This method differs fundamentally from conventional steel bar reinforcement by providing three-dimensional, multidirectional reinforcement rather than oriented strengthening in specific planes. A critical characteristic of this composite system is that the fiber and concrete matrix maintain distinct phases without undergoing chemical interaction, preserving their individual material properties while achieving mechanical interlocking and load transfer through interfacial bonding.

Performance Enhancement Through Fiber Reinforcement

The incorporation of fibers into concrete yields significant improvements in multiple performance parameters. The resulting fiber-reinforced concrete exhibits enhanced resistance to tensile stresses, which is particularly valuable given concrete's inherent weakness in tension. Additionally, fiber reinforcement provides improved abrasion resistance, making it suitable for industrial flooring and pavement applications. The material demonstrates superior performance under dynamic loading conditions, including shock and vibration loads, due to the fiber's ability to bridge microcracks and absorb energy. Furthermore, fiber-reinforced concrete shows improved durability characteristics, including enhanced moisture resistance and frost resistance, which contribute to extended service life in harsh environmental condition.

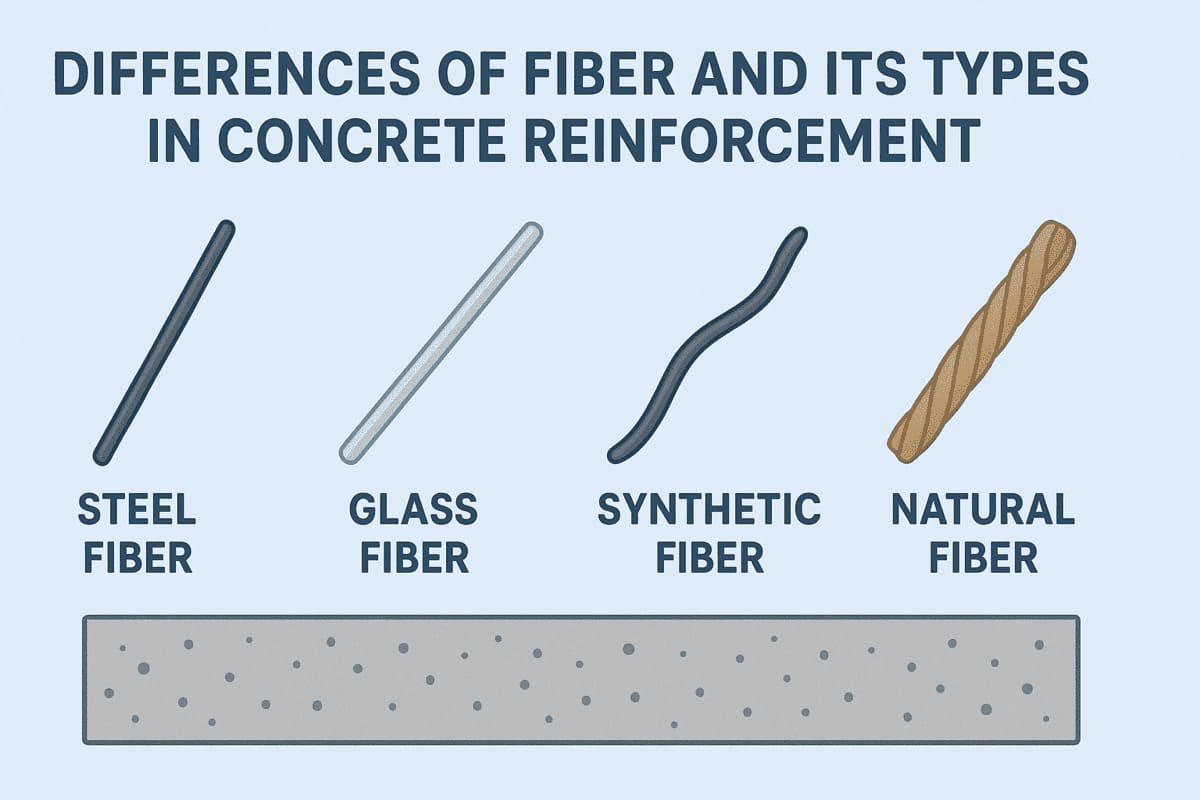

Classification by Material Composition

Fiber reinforcement materials are categorized according to their constituent materials, each offering distinct mechanical and durability properties:

Polypropylene (Polymer) Fiber

Polypropylene fiber represents a synthetic polymer-based reinforcement option characterized by its hydrophobic nature, chemical inertness, and relatively low elastic modulus. These fibers are lightweight, non-corrosive, and demonstrate good resistance to alkali environments, making them compatible with the high pH conditions present in concrete. Polypropylene fibers are commonly employed to control plastic shrinkage cracking during the early stages of concrete curing.

Steel Fiber

Steel fiber consists of short, discrete steel elements that provide high tensile strength and elastic modulus. These fibers are available in various geometries, including straight, hooked-end, crimped, and deformed configurations, which enhance mechanical anchorage within the concrete matrix. Steel fibers significantly improve the post-crack residual strength and ductility of concrete, making them particularly effective for structural applications requiring enhanced load-bearing capacity.

Basalt Fiber

Basalt fiber is manufactured from volcanic rock through a melting and extrusion process, resulting in continuous filaments with excellent mechanical properties. These fibers exhibit high tensile strength, chemical stability, and thermal resistance. Basalt fibers are increasingly recognized for their environmental sustainability and performance characteristics that bridge the gap between glass and carbon fibers.

Glass Fiber (Fiberglass)

Glass fibers are inorganic fibers produced from silica-based raw materials. Alkali-resistant (AR) glass fibers are specifically formulated for concrete applications to withstand the highly alkaline environment of the cement matrix. These fibers provide good tensile strength and are commonly used in thin-section applications such as glass fiber-reinforced concrete (GFRC) panels.

Polyester Fiber

Polyester fibers are synthetic polymer fibers that offer good chemical resistance and dimensional stability. These fibers contribute to crack control and improved impact resistance in concrete applications.

Classification by Dimensional Characteristics

Beyond material composition, fibers are systematically classified according to their dimensional properties, specifically their diameter, which determines their functional role in concrete reinforcement:

Microfiber

Microfibers are characterized by individual filament diameters not exceeding 0.3 millimeters. These fine-diameter fibers are distributed in high numerical densities throughout the concrete matrix and primarily serve to control plastic shrinkage cracking, reduce early-age cracking, and improve surface finish quality. Microfibers function predominantly during the plastic state and early hardening phases of concrete, creating a three-dimensional network that restrains the movement of water and cement particles. This mechanism effectively mitigates plastic settlement cracking and plastic shrinkage cracking, which typically occur within the first 24 hours after placement.

Macrofiber

Macrofibers possess individual filament diameters greater than 0.3 millimeters. These larger-diameter fibers are designed to provide post-crack structural reinforcement and enhance the load-bearing capacity of hardened concrete. Macrofibers become mechanically active after the concrete matrix begins to crack, bridging crack openings and providing residual tensile strength. This characteristic enables macrofibers to partially or fully replace conventional steel mesh reinforcement in certain applications, such as industrial floors, tunnel linings, and precast concrete elements. The increased cross-sectional dimensions of macrofibers provide greater stiffness and improved anchorage within the concrete matrix, facilitating effective stress transfer across crack planes.

Functional Differentiation

The distinction between microfibers and macrofibers reflects their complementary functional roles in fiber-reinforced concrete systems. Microfibers address early-age cracking phenomena and improve concrete workability and cohesion, while macrofibers enhance structural performance and post-crack load-carrying capacity. In many applications, both fiber types may be employed simultaneously in hybrid reinforcement systems to optimize performance across multiple criteria, combining crack control during early ages with enhanced structural behavior in the hardened state.

Recommended products

|  |

| Armotec Fibre | Fibermix Microfiber |