How to calculate the required amount of fiber for concrete

Building technologies do not stand still, constantly improving approaches to fundamental things. Polypropylene fiber has become an integral component of concrete production, greatly improving the characteristics of the solution. What kind of material it is, and in what quantities it is used, we will figure it out in this article.

Contents

- Why concrete fiber is needed

- ArmoTec Fiber

- PolyMesh Macrofiber

- Microfiber for concrete FiberMix

- How to calculate fiber consumption for concrete

Why do we need fiber for concrete

Composite materials are popular in the construction industry due to the vast scope and improvement of the qualities of the original composition. Pure concrete is brittle in tension, therefore, reinforcing elements are used for strengthening: mesh, steel bars, fiber. Metal structures hold the screed or cast element, and polyolefin also protects the surface from the formation of microcracks.

Fibermix brand synthetic fibers made from polymers come in a variety of shapes, weights and lengths. The norm of fiber fibers for concrete preparation depends on the nature of the required work, as well as the size of the additive.

Artificial fibers improve the binding properties of concrete and are evenly distributed throughout the material.

Polymer fiber is used for the purpose of:

- reduce shrinkage of the concrete mix;

- prevent material delamination;

- protect against corrosion;

- to prevent damage from external mechanical impact;

- improve tensile and bending characteristics.

The fiber is added to the mixer at the stage of mixing the dry ingredients. Synthetic fibers are evenly distributed throughout the mixture, after which they are poured with water. The second option – pour the additive into the cement milk, then mix in the rest of the necessary ingredients. The proportion of polypropylene is increased in portions or poured out the entire package at a time.

Fibermix manufactures polyolefin fibers with various uses and characteristics. There are three types of products on the market: ArmoTec, PolyMesh and FiberMix. To select fibers for a specific type of work, consider the technical features of the goods.

ArmoTec fiber

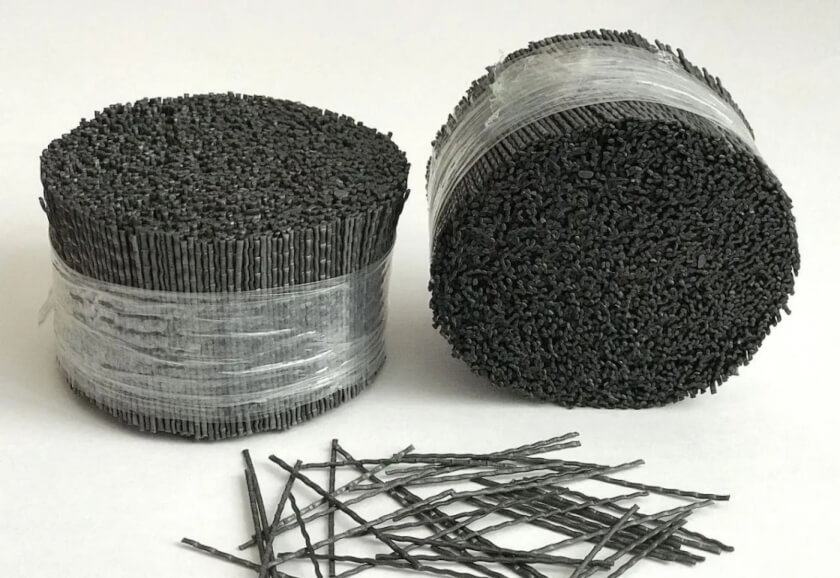

ArmoTec polymer is used for volumetric reinforcement of concrete and shotcrete. Thousands of durable fibers with a corrugated surface are evenly distributed over the entire area of the structure, and protect it from destruction. Polyolefin replaces metal reinforcement in products where resistance to corrosion and chemicals is important.

The length of synthetic fibers ArmoTec 14, 25.40, 55 mm. For 1 kg of material there are 50 000 pieces of corrugated units of graphite color. The consumption of fiber for screed depends on the degree of reinforcement of concrete and resistance to bending. On average, they use from 2 to 6 kg per 1 m3 of the mixture.

ArmoTec applications:

- roads;

- screeds and floors of industrial areas;

- paving slabs;

- piles and bridges;

- cellular concrete;

- warehouses and structures for the oil and chemical industry.

ArmoTec increases the resistance of concrete to sulfates and salts, reduces the final weight of the structure. The polymer additive prevents cracking of the product, absorbs the energy of destruction. Heat-resistant fibers withstand heat and cold without structural changes in the material.

The elasticity modulus of ArmoTec reaches 6 GPa. When selecting a similar indicator of the cement matrix, dispersion reinforcement is improved. The length of the fibers affects the uniform distribution in the mixture. 40 mm fiber is suitable for foam concrete, and 14 mm product interferes with mobile heavy concrete. ArmoTec is compatible with any additives.

PolyMesh Macrofiber

PolyMesh macrofibers are obtained from polypropylene through a series of chemical, thermal and mechanical modifications. The product is so light in weight that it does not settle into the bottom layer of concrete, but provides three-dimensional reinforcement for a fiber length of 38 or 54 mm.

Depending on whether it is necessary to replace the mesh, steel elements, or add reinforcement, it is calculated how much fiber per cube of concrete should be loaded into the mixer. Recommended Density PolyMesh – 2-8 kg per 1 m3 of concrete. In 1 kg of material, the number of fibers reaches 150 000 pieces.

PolyMesh Benefits:

- reinforces concrete structures in bending;

- frost resistant;

- saves the budget and reduces the weight of the product;

- does not break down in alkaline and acid environments;

- is gentle on concrete supply equipment;

- increases impact resistance.

Synthetic macrofiber PolyMesh is added when laying pavement or floors in industrial premises, building tunnels and subways, creating monolithic structures. Polyolefin has a high melting point, which increases the fire resistance of concrete products. The use of fiber significantly speeds up and facilitates concreting.

Macrofiber is produced in graphite color. The tensile strength is 500-600 MPa, which positively affects the crack resistance. Difficult weather conditions do not damage the PolyMesh structure. With frequent frosts and thaws, rains and droughts, the structure remains solid.

Microfiber for concrete FiberMix

FiberMix monofilament levels the surface of the concrete and protects it from the appearance of microcracks during drying. Polypropylene is used instead of steel mesh to speed up construction work and increase project profitability. Microfilaments with a diameter of 20-22 microns are evenly distributed throughout the solution, increasing its viscosity.

An extra millimeter of thread can spoil the structure of the mixture, so the length of the monofilament is selected depending on the intended use. FiberMix microfiber is used in the manufacture of:

- liquid wallpaper;

- dry mixes for construction;

- plasters;

- floor screeds;

- reinforced concrete products.

FiberMix 2 and 3 mm long are added to building mixtures. Threads of 4 mm thicken the plaster, allowing its layer to be compacted and the surface to be leveled. Monofilaments 6 and 12 mm are added to the solution for piece architectural products, paving slabs, plaster finishes and installation of self-leveling floors. Polypropylene 18 mm long is suitable for screeds, cellular concrete, road surfaces, underfloor heating, reinforced concrete structures.

Thin threads create a three-dimensional reinforcement that is not subject to aging. The resulting fiber-reinforced concrete is characterized by increased refractory properties, resistance to temperature extremes. Synthetic threads protect the surface from the penetration of water and chemicals.

A comparison of the characteristics of fiber-reinforced concrete with different contents of polypropylene shows that the optimal amount of synthetic additives is in the range from 0.6 to 2 kg/m3. Mortar shrinkage is reduced by 15% and flexural tensile strength is doubled. Adding more than 2 kg per cube is not economically advantageous, and does not bring tangible improvements in material characteristics.

| Scope of application | Fiber size, mm | Fibre addition rate |

| Industrial floors, cement concrete pavements | 12, 20, 40 | from 1 kg per 1 m3 |

| Screeds, heated floors | 12, 20 | from 0.9 to 1.5 kg per 1 m3 |

| Reinforced concrete, concrete structures and products | 12, 20 | from 0.9 kg per 1 m3 |

| Aerated concrete (foam concrete, non-autoclaved aerated concrete) | 12, 20, 40 | from 0.6 kg to 1.5 kg of fiber per 1 m3 |

| Dry building mixtures (leveling floors, plasters, fillers, grouts, waterproofing, repair compounds) | 3, 6, 12 | from 1 kg per 1 m3 |

| Small-piece products, complex-profile products, small architectural forms | 6, 12 | from 0.9 kg per 1 m3 |

| Paving slabs | 6, 12 | from 0.6 kg to 1.5 kg per 1m³ mix |

| Liquid wallpaper, adhesives | 3 | from 0.5 kg per 1 m3 |

How to calculate fiber consumption for concrete

The amount of fibrous materials for concrete mortar directly depends on the nature of the work, the type and size of the fiber. Deviation from the norm will bring financial losses, and may offset the strengthening effect. Excessively long elements make it difficult to mix and evenly lay the finished fiber-reinforced concrete.

When creating reinforced concrete piles, bridges, hydraulic facilities and structures for the chemical industry, ArmoTec 40-55 mm in length is used at the rate of 6 kg per 1 m3. About 3-4 kg/m3 goes into shotcrete for tunnels and mines. For industrial floors and screeds, it takes 2-3 kg / m3.

Synthetic PolyMesh fibers in the proportion of 8 kg/m3 are used to create reinforced elements of reinforced concrete structures, oil depot structures. 2-4 kg of polypropylene per 1 m3 is spent on the roadbed and screeds in the industrial zone.

To create strong durable structures, 0.9 kg of FiberMix threads per 1 m3 of mortar are poured. To protect the screed from cracks, take 0.6 kg of microfiber per 1 m3. The amount of polyolefin in the concrete mixture and the mixing time directly depends on the length of the fibers: the shorter the thread, the less it is needed per cube of mortar. Monolithic high-strength structures capable of withstanding heavy loads are produced from a fiber 18 mm long at the rate of 2.5 kg / m3.

In the manufacture of a cement-sand mortar for screed, the more synthetic additives are mixed in, the stronger the bending tension is obtained. The quality of concrete after adding polypropylene depends on the degree of distribution of the monofilament. For a sustainable result, the mixer’s operating time is increased by 15% from mixing a clean solution.

Recommended products

|  |

| Microfiber FiberMix | Macrofiber PolyMesh |